IOLseries

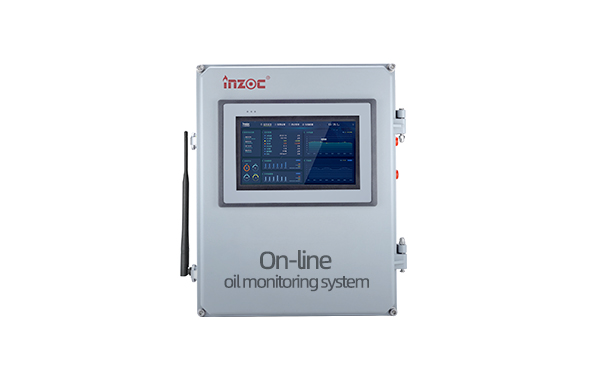

On-line oil monitoring system

The on-line oil monitoring system integrates multi-parameter sensors such as physical and chemical monitoring and pollution degree, and adopts bypass through internal system integration The way oil is introduced into the detection system cycle and the sensor's second-level data acquisition can collect the performance of equipment lubricating oil and gear oil in real time Status, monitoring of oil moisture content, viscosity decay, excessive wear, etc., plus through internal system integration, data calibration, oil properties It can analyze and transmit data, realize intelligent diagnosis of industrial field equipment, and help enterprises manage oil scientifically and with a plan Downtime, planned oil change, reduce the additional loss of equipment unplanned downtime.

Application field:Steel chemical hydraulic gear system, fan gear box, cutter gear system of shield machine, shield machine hydraulic system, electric power Steam turbine system, coal belt conveyor, emulsion pump, cement plant roller, reducer, gear box, port crane, boat grab, etc

Applicable oil:Gear oil, hydraulic oil, turbine oil, diesel oil, insulation oil

The online oil monitoring system integrates physical and chemical, pollution degree and other multi-parameter sensor monitoring, and adopts bypass through internal system integration Oil into the detection system cycle, sensor second l- evel data acquisition, real-time acquisition of equipment lubricating oil, gear oil State, monitoring oil moisture content, - viscosity decay, wear, etc., plus through internal system integration, data calibration, oil properties it can analyze and t ransmit data to realize intelligent diagnosis of industrial field equipment and assist enterprises to manage oil scientifically and in a planned way Shutdown, planned oil change, reduce the additional loss of equipment unexpected shutdown.

Application: steel and chemical hydraulic gear system, fan gear box, shield machine cutter gear system, shield machine hydraulic system, power turbine system, coal belt machine, emulsifying pump, cement plant roller, reducer, gear box, shipping equipment, port crane

Applicable oil: gear oil, hydraulic oil, turbine oil, diesel oil, insulation oil

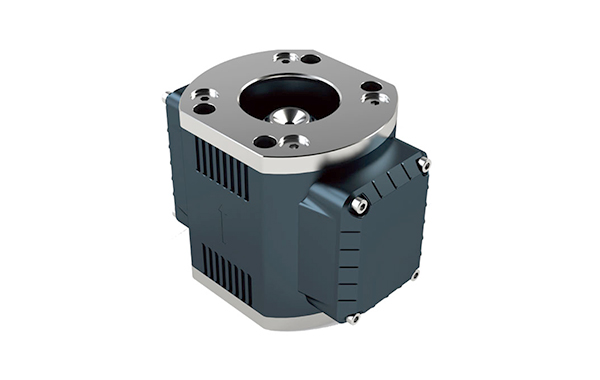

Building block combination and collocation

Working Condition

| Maximum oil temperature | Conventional pressure | Maximum working pressure | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | 40Mpa | -20℃-85℃ | 5000m | 2G | 95% |

Technical parameter

| sensor | range | precision | Resolution | Monitoring index | CODE |

|---|---|---|---|---|---|

| viscosity | 10-1200cp | ±3% | 0.01cp | 40 degree viscosity, dynamic viscosity, kinematic viscosity, density, temperature | V4 |

| Trace moisture | 0-1aw0-10000ppm | ±0.04±10% | 0.01Aw1ppm | Saturation (aw) Moisture content (ppm), temperature | W2A |

| Moisture content | 0-100% | ±0.03% | 0.01% | Moisture content, temperature, moisture content | W2B |

| Oil quality | 1-80 | ±3% | 0.01 | Oil quality, temperature | F2 |

| Metal abrasive particle | ≥30um | ≥95% | Ferromagnetic ≧30um Non-ferromagnetic ≧120um | Ferromagnetic particles, non-ferromagnetic particles, wear concentration | M3 |

| Degree of pollution | 1-600um | RSD≤3% | 1um | Pollution degree grade, total number of particles | J3 |

Optional accessories

| Part name | specification | v | Application scenario | disposition | CODE |

|---|---|---|---|---|---|

| box | Industrial grade | Equipment enclosure | Conventional industrial site | Standard configuration | IOL |

| Power source | AC220/DC24 | Power supply | Conventional industrial site | assorting | PW220/PW24 |

| Screen | 7 inch touch screen | Data local display | Localized display | assorting | D |

| Data transmission | 4g/wifi/Net interface | Cloud platform data transmission | Iot cloud deployment | assorting | W |

| Reducing valve | built-in | Oil circuit decompression | Feed pressure≧3Mpa | assorting | R |

| Built-in low viscosity pump | DC24V | Pressure free system | Oil in≤1bar | assorting | P1 |

| External high viscosity pump | AC220 | Pressure free system | Oil in≤1bar | assorting | P2 |

The standard box is an industrial-grade die-cast aluminum box by default. The protection grade is IP65. The power supply is AC220V power input. Other accessories need to be selected Code description: For example, monitoring 46 hydraulic oil, non-pressure pipeline oil, using cloud data transmission, you can select the corresponding product portfolio system according to the configuration, the combination model is IOL/V4/W2A/J3/W/PW220