IOL-H2series

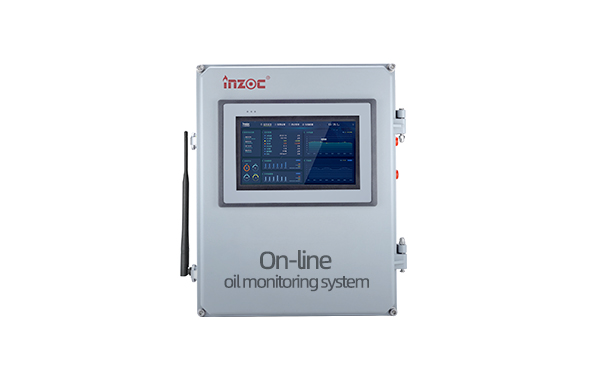

Intelligent on-line oil monitoring system

The new generation of IOL-H series online oil monitoring system adopts digital control, which changes the traditional online monitoring from single oil monitoring to multi-program integration of joint monitoring. The system provides vibration, pressure, flow and other operating status data collection. At the same time, the high-precision sensor technology is extremely sensitive to the abnormal wear, viscosity decay and pollution particles of the oil of the mechanical equipment. The equipment has a rich aging model curve of the oil, and the software system can realize the real-time display of different oil indicators, coordinate curve analysis, historical data search, threshold setting, primary, secondary and tertiary alarm Settings. Support pressure, flow, and other different sensor data access, centralized processing display to achieve intelligent and integrated industrial monitoring. The system has built-in model curves of more than 200 commonly used industrial lubricants, which can be predictive monitoring of oil life quickly. It can quickly adapt to the complex and changeable working conditions of industrial sites, and the edge computing capability has played a crucial role in the predictive maintenance of industrial production equipment.

Application field:Iron and steel metallurgy, petrochemical industry, energy and electricity, cement building materials, large machinery, coal, shield, etc

Built-in model analysis software

Real-time data analysis

Oil life analysis

Automatic control system

Multi-parameter fusion monitoring

Cloud computing

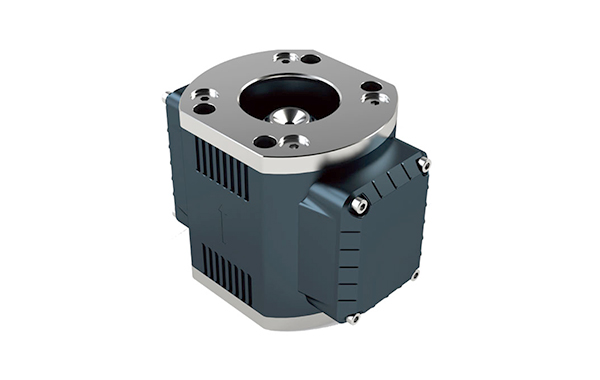

Building block combination and collocation

Changing the complicated selection points and working conditions barriers of traditional online oil monitoring, and the application status of one machine and one condition, the IOL-H series uses automation technology to realize the automatic control of sampling cycle, automatic flow regulation, and intelligent online oil monitoring for fluid pipelines and gear systems with different pressures and viscoses.

Digital analysis

The system is suitable for hydraulic oil, gear oil, diesel oil, turbine oil, etc., and has a strong adaptability to specific oil products, such as phosphate ester hydraulic oil, water glycol hydraulic oil and other special additives can also be monitored.

Intelligent monitoring of the pollution state in the oil, effectively identify the bubbles in the oil, water fibers, impurities, acid value; And the pollution of oil products can be classified and exported to achieve predictive maintenance of equipment.

- Wear analysis: output ferromagnetic wear, non-ferromagnetic wear, wear concentration, total wear.

- Pollution particles: According to NAS1638, ISO4406, GJB and other standards for particle size output, and output according to the size of the corresponding standard pollution level and the total number of particles.

Working Condition

| Maximum oil temperature | Conventional pressure | Maximum working pressure | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | 40Mpa | -20℃-85℃ | 5000m | 2G | 95% |

Technical parameter

| sensor | range | precision | Resolution | Monitoring index | CODE |

|---|---|---|---|---|---|

| viscosity | 10-1200cp | ±3% | 0.01cp | 40 degree viscosity, dynamic viscosity, kinematic viscosity, density, temperature | V4 |

| Trace moisture | 0-1aw0-10000ppm | ±0.04±10% | 0.01Aw1ppm | Saturation (aw) Moisture content (ppm), temperature | W2A |

| Moisture content | 0-100% | ±0.03 | 0.01% | Moisture content, temperature, moisture content | W2B |

| Oil quality | 1-80 | ±3% | 0.01 | Oil quality, temperature | F2 |

| Metal abrasive particle | ≥30um | ≥95% | Ferromagnetic ≧30um Non-ferromagnetic ≧120um | Ferromagnetic particles, non-ferromagnetic particles, wear concentration | M3 |

| Degree of pollution | 1-600um | RSD≤3% | 1um | Pollution degree grade, total number of particles | J3 |

| leak | 0.1ml | - | 0.1ml | Monitoring system leakage | Standard configuration |

| Flow rate | 0-1L/min | ±3% | 1ml | System oil flow | Standard configuration |

| stress | 0-10Mpa | ±3% | 0.1bar | Equipment vibration | Standard configuration |

| Vibration | 0-9G | ±3% | 0.1G | Equipment vibration | Standard configuration |

Optional accessories

| Part name | specification | Feature | Application scenario | disposition | CODE |

|---|---|---|---|---|---|

| pump | Industrial grade | High viscosity gear oil | Gear lubrication condition | assorting | ILX-PW2 |

| Power source | AC220/DC24 | Power supply | Conventional industrial site | assorting | PW220/PW24 |

| Screen | 7 inch touch screen | Data local display | Localized display | assorting | D |

| Data transmission | 4g/wifi/Net interface | Cloud platform data transmission | Iot cloud deployment | assorting | W |

| Reducing valve | built-in | Oil circuit decompression | Feed pressure≧3Mpa | R |