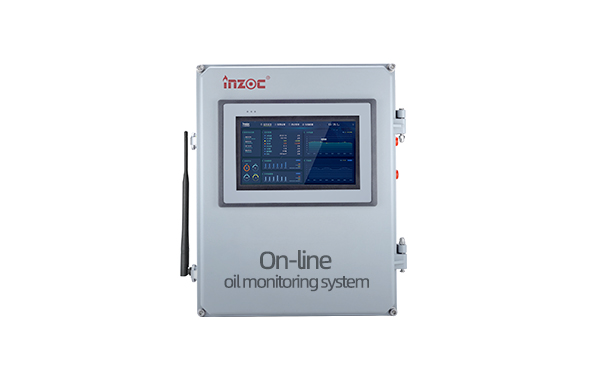

IOL-EX series

Explosion-proof on-line oil monitoring system

The explosion-proof on-line oil monitoring system integrates multi-parameter sensor monitoring such as physical and chemical monitoring and pollution degree, and integrates sensor through internal system It can realize real-time monitoring of oil state. The whole equipment adopts explosion-proof shell and circuit design, internal sensors and other elements Safety circuit design is used in complex dust, petrochemical, flammable gas and other industrial sites can also be safely used. set There is a communication module in the standby, which can help customers build an industrial Internet of Things management system in real time, and the equipment can also support different communications Protocol data output, to achieve docking PLC, PC, host computer, gateway, switch and other data output.

Application field:Energy, power, petrochemical, steel manufacturing, paper machines, steam turbines and other places with high safety requirements

Applicable oil:Gear oil, hydraulic oil, turbine oil, diesel oil, insulation oil

Explosion-proof on-line oil monitoring system integrates physical and chemical, pollution degree and other multi-paramet- er sensor monitoring, and integrates sensors through internal system, can realize the real-time monitoring of oil state. The w- hole equipment adopts explosion-proof shell and circuit design, internal sensors and other components All parts adopt saf- e circuit design, which can be used safely in complex dust, petrochemical, flammable gas and other industrial sites. set Th- e spare is equipped with communication module, which can help customers build industrial Internet of Things manageme- nt system in real time. Meanwhile, the equipment can also support different communication Protocol data output, realize docking PLC, PC, PC, gateway, switch and other data output.

Application: Energy and electric power, petrochemical, steel manufacturing, paper machine, steam turbine and ot- her high safety level requirements

Applicable oil: gear oil, hydraulic oil, turbine oil, diesel oil, insulation oil

Building block combination and collocation

Working Condition

| Maximum oil temperature | Conventional pressure | Maximum working pressure | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | 40Mpa | -20℃-85℃ | 5000m | 2G | 95% |

Technical parameter

| sensor | range | precision | Resolution | Monitoring index | CODE |

|---|---|---|---|---|---|

| viscosity | 10-1200cp | ±3% | 0.01cp | 40Degree viscosity, dynamic viscosity, kinematic viscosity, density, temperature | V4 |

| Trace moisture | 0-1aw0-10000ppm | ±0.04±10% | 0.01Aw1ppm | Saturation (aw) Moisture content (ppm), temperature | W2A |

| Moisture content | 0-100% | ±0.03 | 0.01% | Moisture content, temperature, moisture content | W2B |

| Oil quality | 1-80 | ±3% | 0.01 | Oil quality, temperature | F2 |

| Metal abrasive particle | ≥30um | ≥95% | Ferromagnetic ≧30um Non-ferromagnetic ≧120um | Ferromagnetic particles, non-ferromagnetic particles, wear concentration | M3 |

| Degree of pollution | 1-600um | RSD≤3% | 1um | Pollution degree grade, total number of particles | J3 |

Optional accessories

| Part name | specification | Feature | Application scenario | disposition | CODE |

|---|---|---|---|---|---|

| Explosion-proof housing | IIB T4 Gb anti-explosion | Equipment enclosure | Explosion-proof industrial site | Standard configuration | IOL-EX |

| Explosion-proof power supply | AC220/DC24 | Power supply | Explosion-proof industrial site | assorting | PW220/PW24 |

| Explosion-proof cable | anti-explosion | Power input | Explosion-proof scenario | assorting | X |

| Data transmission | 4g/wifi/Net interface | Cloud platform data transmission | Iot cloud deployment | assorting | W |

| Reducing valve | built-in | Oil circuit decompression | Feed pressure≧20bar | assorting | R |

| Built-in low viscosity pump | DC24V | Pressure free system | Oil in≤1bar | assorting | P1 |

| External high viscosity pump | AC220 | Pressure Free system | Feed ≤1bar | Optional | P2 |