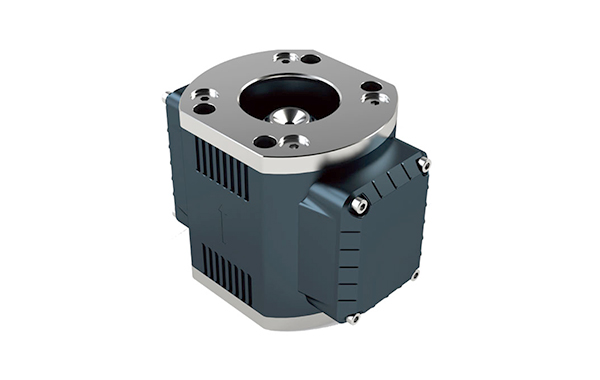

GYD12(A) series

Intrinsic safety type oil quality monitoring sensor for mine

The intrinsic safety oil sensor for mining integrates oil data acquisition of viscosity moisture, pollution particles and wear particles through an innovative structural design Technology, a sensor according to the actual needs of the site for autonomous data acquisition, the new technology has changed the traditional coal mine embedded sensor single The miniaturized design has great advantages in the integrated installation of coal mine equipment, and the sensor integrates multiple parameters inside The output module, data calibration module, reserved RS485 communication interface, easy to connect to the industrial control system for data fusion, with intelligence Match Technology oil analysis upper computer software to achieve a more scientific coal mine equipment oil life prediction.

Integrated sensing technology

Suitable for integrated installation of different devices

Multi-parameter monitoring

Built-in model algorithm

Multi-dimensional data acquisition

Application field:Shearer, boring machine, coal belt machine, coal emulsion pump, reducer, scraper, coal special equipment

Applicable oil:Gear oil, hydraulic oil, turbine oil, diesel oil, special oil for coal equipment

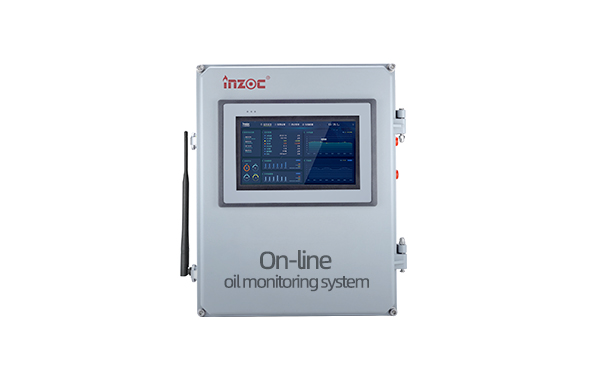

Building block combination and collocation

Working Condition

| Maximum oil temperature | Oil line pressure | Flow rate of oil circuit | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | ≤1m/s | -20℃-85℃ | 5000m | 2G | 95% |

Specificationr

| argument | range | precision | Resolution | CODE |

|---|---|---|---|---|

| Ferromagnetic particle | 30-800um | ≥95% | ferromagnetic≧30um | M3 |

| Non-ferromagnetic particles | 120-1600um | ≥95% | non-ferromagnetic≧120um | |

| Wear concentration | Real-time value | 1mg/l | 1mg/l | |

| 24H total number of particles | Real-time value | 1 | 1 | |

| Degree of pollution | 1-600um | RSD≤3% | 1um | J3 |

| Moisture content | 0-10000ppm | ±10% | 1ppm | W2A |

| 饱和度 | 0-1aw | ±0.04 | 0.01aw | W2A |

| Moisture content | 0-100% | ±0.03(Maximum range) | 0.01% | W2B |

| Oil quality | 1-80 | ±3% | 0.01 | V4 |

| Dynamic viscosity | 10-1200CP | ±3% | 0.01cp | |

| temperature | 20℃-85℃ | 0.1℃or ±3% | 0.01℃ | |

| density | 600 ~1500 kg. m³ | ±3% | 0.01kg. m³ | |

| Installation package: high pressure tubing, joint | ||||

| Options: real-time kinematic viscosity, V40 viscosity, V100 viscosity, viscosity index, conductivity | ||||

According to the field needs, can be matched with the model group number, such as monitoring gear oil, can be combined with the code GYD12/M3/W2B/V3

The accuracy corresponding to the above performance parameters is the typical value of 25℃. In the case of exceeding the requirements of the system working condition, the data may be biased, and the accuracy will change according to the pressure, flow rate, vibration and other data.

Electrical properties

| Communication interface | Data transmission | power | voltage | weight | Shell material | Cable length | Class of protection |

|---|---|---|---|---|---|---|---|

| 6 core jet jack | RS485/232 | ≤5W | AC127V | 7000G | 316L | 1.5m | IP65 |

The above performance indicators are suitable for conventional industrial site installation and use, encounter complex and harsh outdoor environment and fluid property changes, customized design according to site requirements, you can also contact our sales engineers for recommendations