For the industrial working environment with high explosion-proof requirements, such as coal mine, chemical industry, petroleum, smelting and other flammable and explosive working environment, the oil monitoring technology is subject to many restrictions in the application process. On the basis of the original oil monitoring technology, Zhimatch technology has once again made a technical breakthrough, developed an explosion-proof online oil monitoring system, and has also obtained explosion-proof certification, greatly avoiding the occurrence of safety accidents. This research and development of intelligent match technology has promoted the development of industrial applications of oil monitoring technology. For complex industrial sites, we provide circuit design with intrinsic safety circuit design, safe and reliable, plus optional explosion-proof shell design, for the intelligent operation and maintenance of equipment escort.

Program advantage

Safe and reliable

The product has MA coal safety, KA mine safety certification, in line with site safety requirements.

Data output

Three standardized data output modes support coal field private network, wired, industrial cloud platform.

Comprehensive ecology

Focus on coal industry partners to jointly build smart coal predictive maintenance.

Leading technology

Industry-leading inspection technology, providing a variety of coal-specific sensor acquisition systems.

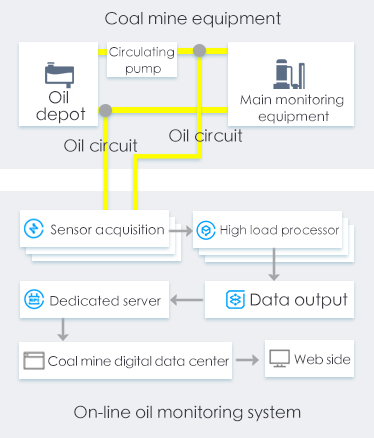

Coal mine equipment solutions

Bypass monitoring

-Coal safety/mine safety online monitoring system

The online oil monitoring system adopts the form of main road opening or interface conversion, such as the need to monitor the coal belt machine, select a suitable position in the main return oil pipeline of the belt oil road, introduce oil to the interface of online oil monitoring, and realize the oil circuit circulation. Data collection, data analysis, data display (localization), and data upload can be integrated, truly saving worry, money and effort, and monitoring data is stable and reliable.

Monitoring index

- viscosity:Dynamic viscosity, kinematic viscosity, 40 degree viscosity.

- hydration:Moisture content, saturation, moisture content.

- Oil quality:Additives, lysates, impurities, acid value, moisture, particle pollution (characteristic indicators).

- Wear particle:Ferromagnetic wear particles, non-ferromagnetic wear particles, wear concentration (ppm).

- Pollution particle:Particle distribution, particle grade.

Communication mode

- RS485:Provides standard output protocol, can be directly connected to the coal mine data acquisition unit.

- Net interface:Standard output protocol, can be directly connected to the coal mine private switch, multi-channel data acquisition.

- Optical fiber:Standard output protocol, can be directly connected to the coal mine private switch, multi-channel data acquisition.

- 4G:Built-in professional Internet of things or the use of coal mine designated dedicated gateway, coal mine dedicated cloud platform for data transmission.

Applicable oil

- Industrial gear oil:L-CKD 220/320/460/680 Etc.,Equipment gear box use, and other closed gear lubrication place.

- Hydraulic oil:L-HM 46/68, etc., hydraulic system use, such as hydraulic support, hydraulic system of construction machinery, hydraulic arm of shearer, etc.

- Air compressor oil:Divided screw and piston two, air compressor and other equipment special.

- Diesel engine oil:Transport equipment, construction vehicles, mining equipment and other diesel engine power system use.

- Antifreeze solution:Transportation equipment, construction vehicles, mining equipment and other water tank use.

- Gear oil:GL-5 grade heavy duty vehicle gear oil.

- Hydraulic transmission oil:Construction machinery, equipment hydraulic transmission system use.

Key monitoring equipment

Customer case

They all trust our oil monitoring technology

A coal mine of Guoneng Group

Provide reliable and compliant on-line oil inspection system

Based on the reliable oil monitoring technology of coal mine equipment, Smart Match works with partners to carry oil monitoring technology in the technical transformation of important equipment such as national energy coal mine belt conveyor, emulsion pump, scraper, etc., to ensure the stable operation of equipment and provide reliable data support for the safe production of equipment.

Shaanxi Coal Group

Hongliulin coal mine loading station coal feeder hydraulic station

Help the high and low pressure hydraulic system of coal feeder hydraulic station in Hongliulin Coal Mine loading station of Shaanxi Coal Group to achieve multi-point sound signal, single point calculation and processing program, monitor the distribution of oil pollution particles in the hydraulic system, and solve the problems such as unclear filtration effect of the hydraulic station, valve block blockage, unclear aging of oil products, and frequent inspection, helping enterprises to achieve scientific management.

China Coal Huajin Group Co., LTD

Hejin Wangjialing Coal mine - belt machine head reducer lubrication system

For China Coal Huajin Group Co., LTD., Hejin Wangjialing Coal Mine - belt conveyor head reducer lubrication system to provide oil online monitoring solutions. Monitoring indicators: viscosity, temperature, oil quality, water-bearing wear particles.

China Huaneng Group

Gao Tou Kiln coal mine - emulsion pump crankcase lubrication system

Provide pre-installed online oil monitoring system for Huaneng Gaotou Kiln coal mine - emulsion pump crankcase lubrication system, mine safety monitoring system is specially designed for coal and other related industries, providing great help for the construction of smart mines.