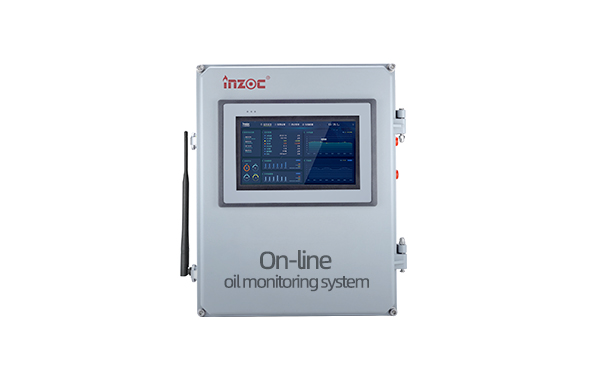

YJY12 series

Intrinsic safety on-line oil monitoring system for mine

YJY12The intrinsic safety type online oil monitor for mining is composed of oil quality data acquisition module (wear, viscosity, moisture, dielectric constant) Temperature, density, cleanliness sensor), equipment status acquisition module (pressure, vibration, flow), data processing module, object Network remote communication module. The system can realize coal detection by installing oil on-line monitoring in the recycling and return oil circuit of coal mine equipment Mining machinery equipment lubrication system, gearbox transmission system, hydraulic system and other oil aging state of real-time monitoring, coordination The internal oil aging model algorithm provides scientific monitoring data for oil life status and equipment operation status in real time to ensure The safe operation of the equipment and the design of various communication protocols provide powerful data support for the data visualization of intelligent coal mine.

Software system

- Can be directly transmitted to the central control system through RS485/ optical fiber

- Monitor can run directly on the host computer

- Standardized data output, fast fault diagnosis and analysis

- Abnormal gear wear Output wear concentration, wear distribution

- The monitoring system cannot be accessed

- Implementation for Integrated deployment

- Self-set alarm range, first and second level warning

- Free switching between different devices, multi-channel monitoring

- Comprehensive analysis model, rapid comprehensive analysis of oil deterioration

Application field:Shearer, boring machine, belt machine, emulsion system, crusher, scraper, reducer

Applicable oil:Gear oil, hydraulic oil, turbine oil, diesel oil, special oil for coal equipment

Structure size

Working Condition

| Maximum oil temperature | Normal pressure | Maximum working pressure | Working ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | 40Mpa | -20℃-85℃ | 5000m | 2G | 95% |

Technical parameter

| sensor | range | precision | Resolution | Monitoring index | CODE |

|---|---|---|---|---|---|

| viscosity | 10-1200cp | ±3% | 0.01cp | 40Degree viscosity, dynamic viscosity, kinematic viscosity, density, temperature | V4 |

| Trace moisture | 0-1aw0-10000ppm | ±0.04±10% | 0.01Aw1ppm | Saturation (aw) Moisture content (ppm), temperature | W2A |

| Moisture content | 0-100% | ±0.03 | 0.01% | Moisture content, temperature, moisture content | W2B |

| Oil quality | 1-80 | ±3% | 0.01 | Oil quality, temperature | F2 |

| Metal abrasive particle | ≥30um | ≥95% | Ferromagnetic ≧30um Non-ferromagnetic ≧120um | Ferromagnetic particles, non-ferromagnetic particles, wear concentration | M3 |

| Degree of pollution | 1-600um | RSD≤3% | 1um | Pollution degree grade, total number of particles | J3 |

| stress | 0-10MPa | ±3% | 0.1bar | System oil circuit pressure | Standard configuration |

| Flow rate | 0-1L/min | ±3% | 1ml | System oil flow | Standard configuration |

| Vibration | 0-9.8m²/s | ±3% | 1mV/m·s² | Equipment vibration | Standard configuration |

| leak | 0.1ml | 0.1ml | Whether the equipment leaks | Standard configuration |

Optional accessories

| Part name | specification | Feature | Application scenario | disposition | CODE |

|---|---|---|---|---|---|

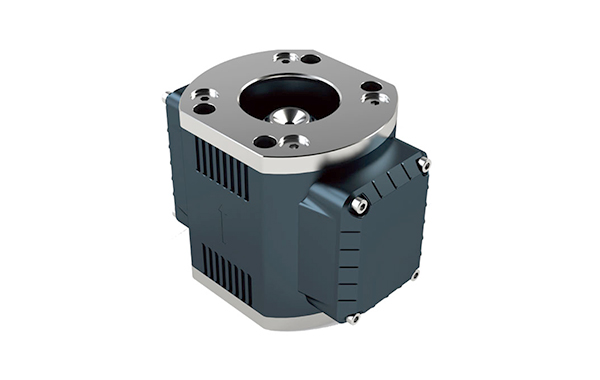

| Explosion-proof housing | MA alloy housing | Equipment enclosure | Mine site | Standard configuration | |

| Explosion-proof power supply | AC127 | Power supply | Mine site | assorting | PW127 |

| Explosion-proof cable | anti-explosion | Power input | Power source | assorting | Standard 5m |

| Data transmission | RS485 | Data transmission | Wired communication | Standard configuration | |

| Explosion-proof gateway | custom | Intranet 4G communication | Private number segment network card | assorting | R |

| Gain antenna | Signal enhancement | Standard configuration | |||

| MA External pump | AC127 | Pressure free system | Oil in≤1bar | assorting | P2-W |