The main reducer, grate cooler and roller press of rotary kiln are the core equipment in the daily production of cement factory, and the normal operation of the equipment affects the production capacity and economic benefit of the whole enterprise. At present, the management methods for these main equipment still stay in the stage of conventional lubricating oil sampling and inspection, the frequency of inspection is different, the method of taking oil and the secondary pollution in the transportation process may lead to the authenticity of the data, coupled with the impact of timeliness, it is not possible to determine the quality of lubricating oil and equipment failure through the indicators of lubricating oil in a timely manner. Therefore, for enterprises, it will cause oil waste caused by inaccurate and timely addition of lubricating oil and equipment failure problems caused by timely detection of equipment maintenance problems, and may even cause unplanned and unplanned downtime, resulting in huge economic losses for enterprises, and serious personal safety problems. Therefore, if we can provide an effective online real-time monitoring program for the lubrication system of the core equipment of the cement plant and achieve scientific management and diagnosis of the core equipment, we can not only help the enterprise solve the problem of oil waste and excessive inventory pressure of spare parts in the warehouse, but also effectively understand the safety problems of equipment operation, which can play a very important role in improving the work efficiency of the enterprise.

Program advantage

Close application

Close to cement mill, raw material mill, roller press and other equipment applications, to provide standardized products and services.

Data output

Three standardized data output modes support coal field private network, wired, industrial cloud platform.

Standard report

For the harsh environment of the cement industry, the special model algorithm ADAPTS to the changes of oil products.

Security linkage

The circuit adopts linkage design to start and stop linkage with the generating device to realize linkage monitoring.

The system has three deployment modes

Bypass monitoring

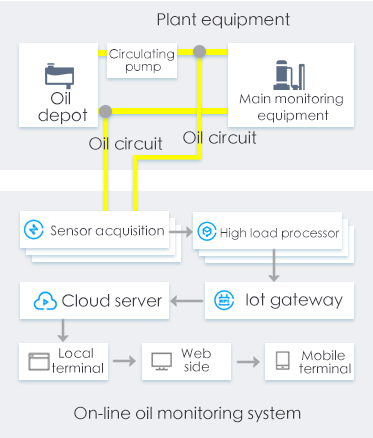

-On-line monitoring system

The online oil monitoring system adopts the form of main road opening or interface switching, such as the need to monitor the rolling mill oil road, select a suitable position in the main return pipeline of the rolling mill oil road, introduce the oil to the interface of online oil monitoring, and realize the oil circuit circulation. Data collection, data analysis, data display (localization), and data upload cloud servers can be integrated, truly saving worry, money and effort, and monitoring data is stable and reliable.

Main road monitoring

-Multi-point acquisition sensor

In different equipment, there are many key data points, and the method of multi-point collection and single point processing can greatly save costs. During installation, holes can be directly made in the system pipeline, and the sensor can be embedded in the pipeline. The sensor is designed to resist corrosion, impact, pressure and high stability, and can collect multi-point oil aging information during system operation. Discover unexpected faults such as water intake and pollution in time, quickly locate the fault location, and achieve accurate collection.

Main road monitoring

-Multifunctional sensor

The main road multi-function monitoring is suitable for the transformation of the lubrication system and the use of large-area deployment. The sensor is installed by using flange transfer or pipeline transformation on the lubrication pipe road. The sensor is suitable for the installation of a variety of different standard flanges and different pipe diameters, and the internal integration of a variety of monitoring indicators. The data can be uploaded and displayed in a centralized mode to maximize the economic effect.

Application equipment

Customer case

They all trust our oil monitoring technology

Heavy Mountain Group - Luzhong Cement

Roll reducer thin oil lubrication station system monitoring

Conventional lubricating oil sampling and inspection stage, inspection frequency is different, the method of taking oil and the secondary pollution in the transportation process may lead to the authenticity of the data, intelligent match online real-time monitoring system can solve this problem.

China National Building Materials - Southern Cement

Coal mill reducer lubrication system monitoring case

To provide an effective online real-time monitoring program for the lubrication system of the core equipment of cement plant, so as to achieve scientific management and diagnosis of the core equipment, not only can help enterprises solve the problem of oil waste, the problem of excessive inventory pressure of spare parts in the warehouse, but also can effectively understand the safety problems of equipment operation, which can play a very important role in improving the work efficiency of enterprises.

Chengdu Lafarge Cement

Gear lubrication station monitoring case

The lubrication system of the core equipment of cement plant provides an effective online real-time monitoring program to achieve scientific management and diagnosis of the core equipment, which can not only help enterprises solve the problem of oil waste and excessive inventory pressure of spare parts in the warehouse, but also effectively understand the safety problems of equipment operation, which can play a very important role in improving the work efficiency of enterprises.

Shanshui cement

Provide reliable gear box monitoring system

Conventional lubricating oil sampling and inspection stage, inspection frequency is different, the method of taking oil and the secondary pollution in the transportation process may lead to the authenticity of the data, intelligent match online real-time monitoring system can solve this problem.