With the vigorous development of the wind power industry in recent years, the cumulative installed capacity is also a geometric multiple growth, and as a very important part of the gear box part of the complete equipment, maintenance costs are very high, so the effective online monitoring of gear box components to judge the wear of gear box components is very important. The analysis of the lubricating oil status of the gear box through online monitoring can play a key role.

Program advantage

anti-interference

The unique structural design prevents the impact of high flow of the gearbox and ensures the stability of the sensor data.

Communication protocol

Standardized data output protocol for integrated access of different fault diagnosis systems to create a comprehensive system.

Standard output

Provide readable data in line with national standards and industry standards, reduce the difficulty of data analysis, and achieve rapid fault analysis.

Reliable quality

The system design guarantees a service life of more than 5 years, reducing the additional cost of subsequent maintenance.

Two deployment plans for smart wind power

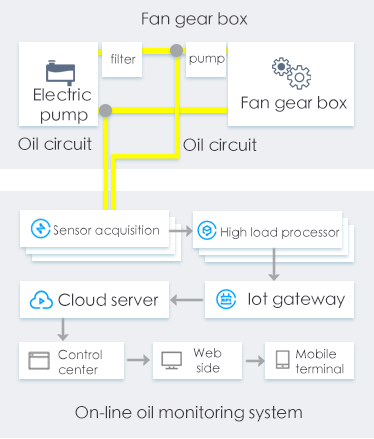

Bypass scheme

-Wind power intelligent oil monitoring system

Wind power smart oil monitoring system adopts a new SAE tee interface between the original SAE joint and the mechanical pump to introduce oil to the online oil monitoring sensor, and the oil return port is connected to the pressure measuring joint or plug of the filter to achieve oil circuit circulation. Data collection, data analysis, data display (localization), and data upload cloud servers can be integrated, truly saving worry, money and effort, and monitoring data is stable and reliable.

Monitoring index:Viscosity, oil quality, temperature, density, moisture content, saturation, moisture content, ferromagnetic wear particles, non-ferromagnetic wear particles, wear concentration

Adaptive flange:SAE2.0\3.0\2.5

Adapted oil:Fan gear oil

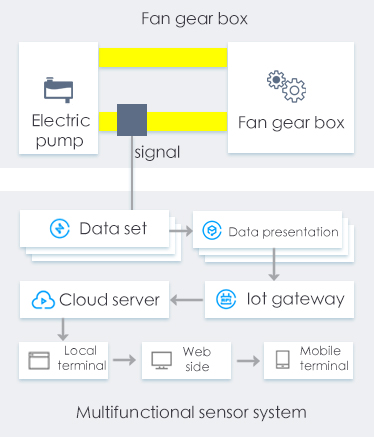

Main route scheme

-Wind power intelligent oil monitoring system

The main multi-energy scheme adopts the form of flange joint, and the sensor integrates a variety of monitoring indicators. One sensor can replace the traditional three sensor monitoring indicators. The ingenious internal design solves the problem of the detection rate of wear particles under large flow rate, ensuring that the sensor can perform the condition monitoring in the best working state under different speed and flow rate. To ensure the safety of the operation of the fan, the design of the flange adapter ADAPTS to more than 90% of the fan installation on the market, so as to achieve high adaptability, and the economy currently occupies more than 50% of the market market share of the fan

Monitoring index:Viscosity, oil quality, temperature, density, moisture content, saturation, moisture content, ferromagnetic wear particles, non-ferromagnetic wear particles, wear concentration

Adaptive flange:SAE2.0\3.0\2.5

Adapted oil:Fan gear oil

Predictive maintenance solutions for wind power

Customized by the original factory

Fan production supply chain customization services

Adapt to personalized appearance, communication mode, interface customization and other product solutions, develop an integrated wind power gearbox oil monitoring system, and jointly build an intelligent fan operation and maintenance system.

Fan reconstruction scheme

Customized design for operational fans

In the technical upgrading and transformation of the wind farm that has been working normally, the technical audit is carried out jointly with the wind farm operation and maintenance unit, and the online oil monitoring system is added on the premise that the normal operation of the fan is not damaged.

Joint deployment

Wind power intelligent operation and maintenance system supplier

Cooperate with excellent enterprises with capable wind power operation and maintenance monitoring platform to provide technical support for oil monitoring hardware and build intelligent predictive wind power operation and maintenance.

Customer case

They all trust our oil monitoring technology

Sany Wind Power

Factory pre-installed oil sensor case

We provide customers with a variety of installation methods of the oil sensor system, suitable for different models of gear box installation, greatly saving the later installation and adaptation process of parts changes, reliable sensor system can directly output 40 degrees of viscosity data, the minimum monitoring of 30um wear particles, help customers to achieve intelligent upgrade.

A smart wind power operation and maintenance technology company

Provides reliable integrated oil monitoring technology

To provide customers with support in the sensor underlying technology, research the characteristics of wind power industry models to promote the construction of smart wind power, we also provide standardized data output mode, to assist customers in the rapid integration of wind turbine operation and maintenance system standardization.

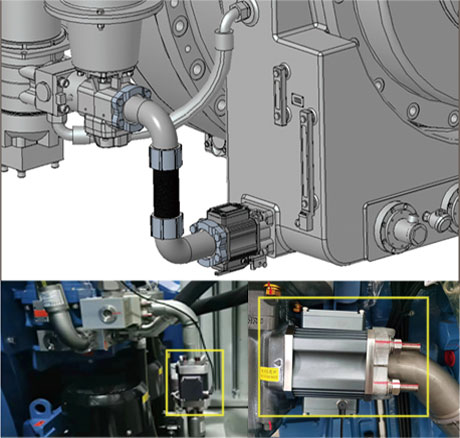

Yunda Stock

Provide wind power gear main road monitoring program

We provide customers with a variety of installation methods of oil sensor system, suitable for different models of tooth soft box installation, greatly saving the later installation and adaptation process of parts changes, reliable sensor system can directly output 40 degrees of viscosity data, the minimum monitoring of 30um wear particles, help customers to achieve intelligent upgrade.

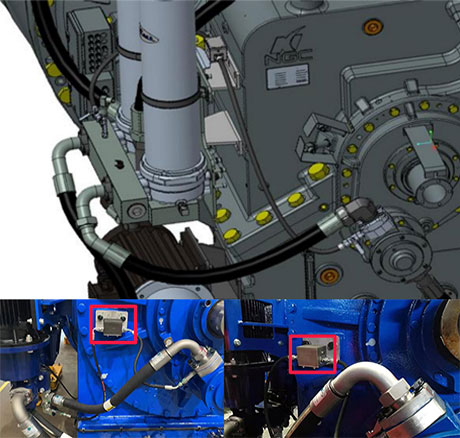

China Three Gorges Corporation

Fujian Three Gorges offshore wind power gearbox electric pump - bypass installation scheme

To provide customers with support in the sensor underlying technology, research the characteristics of wind power industry models to promote the construction of smart wind power, we also provide standardized data output mode, to assist customers in the rapid integration of wind turbine operation and maintenance system standardization.