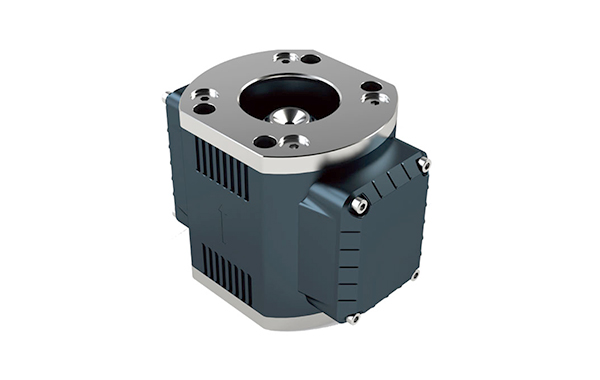

IFM-3 series

Metal wear particle sensor

IFM series oil metal wear particle sensor adopts the industry leading high-precision wear particle detector and back-end micro-processing circuit system Has become the leading technical performance of oil wear detection sensor; High detection accuracy, high stability, small size, is online oil The star products of wear monitoring in monitoring have been highly praised and recognized by the industry. The sensor can simultaneously detect ferromagnetism in oil The number and size distribution of sexual particles and non-ferromagnetic particles can be detected at least 30um ferromagnetic particles and 120um non-ferromagnetic particles Up to 15 abrasive size channels for more accurate equipment failure monitoring; 24-hour particle count to avoid missing any wear information With back-end RS485 MODBUS RTU digital communication, the equipment wear information can be transmitted to the acquisition equipment in a stable and timely manner It is the fist weapon of equipment wear and fault detection.

High precisionAdopt the latest electromagnetic inspectionMeasuring technique, ferromagnetic mostSmall resolution to 30um

anti-interferenceAnti-interference signal structureMore accurate signal output

Fine detectionCan detect 15 passesTrace wear information, checkClearer measurement

Lightweight designPrecise analysis of wearConcentration and grinding

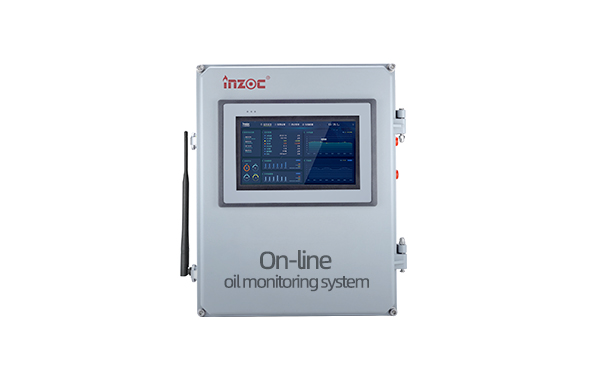

Data transmission mode

Dimensions and installation

Working Condition

| Maximum oil temperature | Oil line pressure | Flow rate of oil circuit | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | ≤1m/s | -20℃-85℃ | 5000m | 2G | 95% |

Specificationr

| Model selection | Ferromagnetic wear detection channel | Non-ferromagnetic wear detection channel | Total particle count | Particle concentration | Velocity of flow |

|---|---|---|---|---|---|

| IFM-3 | 30~50um | 24h Total number of ferromagnetic particles | Ferromagnetic concentrationNon-ferromagnetic concentration(mg/L) | Standard configuration | |

| 50~100um | 120~200um | ||||

| 100~200um | 200~400um | ||||

| 200~400um | 400~800um | ||||

| 400~800um | 800~1600um | ||||

| >800um | >1600um | ||||

| Detection rate | ≥95%(model) | Total wear particles | Particle concentration | ||

| Ferromagnetic elements: iron, cobalt, nickel, neodymium, boron, samarium, cobalt, as well as rare earth metals (lanthanides), other ferromagnetic alloy metals Non-ferromagnetic elements: copper, aluminum, magnesium, zinc, alloy metal, etc | |||||

The above metal elements only represent the range that the product can monitor, and the sensor cannot distinguish the type of element

The accuracy corresponding to the above performance parameters is a typical value. In the case of exceeding the requirements of the system working condition, the data may be biased, and the accuracy will change according to the pressure, flow rate, vibration and other data.

Electrical properties

| Communication interface | Data transmission | power | voltage | 电压 | Shell material | Cable length | Class of protection |

|---|---|---|---|---|---|---|---|

| 6 core jet jack | RS485/232 | ≤2W | DC 9V~36V | 850G | 316L | 1.5m | IP65 |

The above performance indicators are suitable for conventional industrial site installation and use, encounter complex and harsh outdoor environment and fluid property changes, customized design according to site requirements, you can also contact our sales engineers for recommendations