Compressor to run well, in addition to the performance of the unit itself (including auxiliary machinery and its system), the performance of the process pipe network, installation quality, etc., must also be carefully operated, carefully completed in the operation of various monitoring and inspection, and carefully analyzed and processed the obtained data. Compressor types are different, there are many types of driving machine, motor, steam turbine and gas turbine, so the operation method is not the same, especially the operation of chemical compressor and chemical process operation is closely related

Program advantage

Safe and reliable

Authoritative explosion-proof certification system, high strength pressure, high temperature, high protection design for harsh environment.

Rich scene

Built-in rich model, suitable for oil film oil, hydraulic oil, gear oil and other applications.

Rapid deployment

Support local LAN, cloud services, local RS485 data transmission mode.

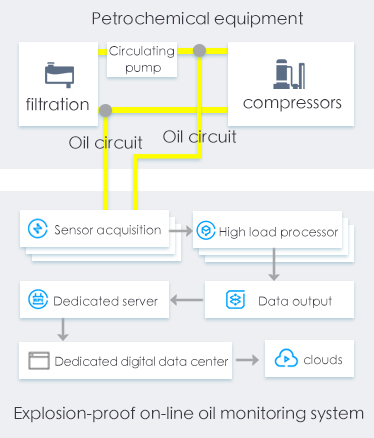

Explosion-proof deployment solution

Bypass monitoring

-Explosion-proof on-line monitoring system

Explosion-proof online oil monitoring system The whole machine adopts explosion-proof design, provides I/II class explosion-proof requirements of products, in line with dust, flammable and explosive environment installation applicable. The product provides wired and wireless transmission methods for data transmission, which can be quickly connected to the data link of the terminal site. At the same time, the sensor inside the device can be freely applied on the oil circuit such as high pressure or low pressure for special applications in the petrochemical industry.

Explosion-proof mark

EX d IIB T4 Gb EX ib I Mb

Monitoring index

- viscosity:Dynamic viscosity, kinematic viscosity, 40 degree viscosity.

- hydration:Moisture content, saturation, moisture content.

- Oil quality:Additives, lysates, impurities, acid value, moisture, particle pollution (characteristic indicators).

- Wear particle:Ferromagnetic wear particles, non-ferromagnetic wear particles, wear concentration (ppm).

- Pollution particle:Particle distribution, particle grade.

Communication mode

- RS485:Provides standard output protocol, can be directly connected to the coal mine data acquisition unit.

- Net interface:Standard output protocol,It can be directly connected to the coal mine private switch for multi-channel data acquisition.

- Optical fiber:Standard output protocol, can be directly connected to the coal mine private switch, multi-channel data acquisition.

- 4G:Built-in professional Internet of things or the use of coal mine designated dedicated gateway, coal mine dedicated cloud platform for data transmission.

Applicable oil

- Industrial gear oil:L-CKD 220/320/460/680等,Equipment gear box use, and other closed gear lubrication place.

- Hydraulic oil:L-HM 46/68 Etc.,Hydraulic system use, such as hydraulic support, construction machinery hydraulic system, shearer hydraulic arm, etc.

- Air compressor oil:Divided screw and piston two, air compressor and other equipment special.

- Diesel engine oil:Transport equipment, construction vehicles, mining equipment and other diesel engine power system use.

- Antifreeze solution:Transportation equipment, construction vehicles, mining equipment and other water tank use.

- Gear oil:GL-5 grade heavy duty vehicle gear oil.

- Hydraulic transmission oil:Construction machinery, equipment hydraulic transmission system use.

Customer case

They all trust our oil monitoring technology

Cnooc Hainan drilling platform

Drilling platform compressor

Smart Match and CNOOC Information Technology to provide reliable oil monitoring sensor for drilling platform flash steam compressor, combined with CNOOC Information DG information processing technology, jointly build a localized data monitoring system to grasp real-time compressor oil operation status.

A petrochemical plant of petrochina

Case study of equipment integrated oil monitoring

CNPC subsidiary plant in the ethylene cracking furnace flue gas nox standard renovation project, for the compressor oil monitoring proposed technical transformation, Zhimatch technology to provide customers with a comprehensive leading oil monitoring products, help realize the intelligent upgrade of equipment.

Baihong Industrial Holding Co., LTD

Baihong Petrochemical - Turbine system monitoring

Smart Match provides reliable oil monitoring system for Baihong Industrial Holdings Co., LTD. In the oil monitoring project of turbine system, we jointly build a localized data monitoring system to grasp the oil running status of the turbine in real time.

Shandong Union Chemical Group

Centrifugal compressor monitoring

The second type of explosion-proof intelligent online oil monitoring system launched by Wise Match Technology has been applied to the oil monitoring project of Shandong Union Chemical Group and centrifugal compressor, providing a comprehensive and leading oil monitoring and helping to realize the intelligent upgrade of equipment.