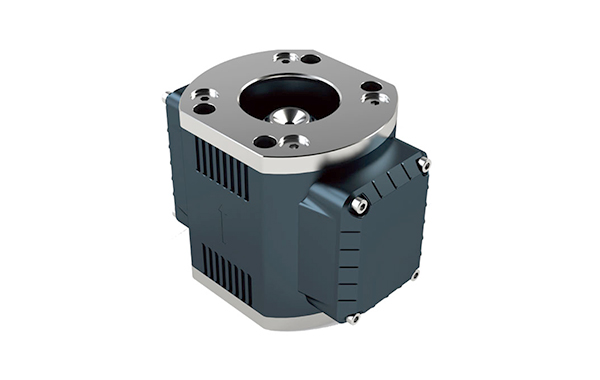

ISL-Z2 series

Main road multi-function oil sensor

SL-Z2The main multifunctional oil sensor adopts the patented multifunctional integrated detection technology and the industry-leading back-end data processing module to form a large-range, high-precision, multifunctional oil comprehensive detection sensor, which greatly reduces the industry problems such as online oil monitoring field installation repeated opening holes and installation controls, and is a representative product with large range and multi-parameters in the industry. The sensor can be adapted to the flange conversion installation of different standards, suitable for the integrated installation of fan gear box, power system, diesel engine, Marine diesel engine and other systems, and can complete the detection of viscosity, density, dielectric constant, moisture content, temperature and wear particles at one time. At the same time, with the internal model data, optional: Real-time kinematic viscosity, 40℃ kinematic viscosity, 100℃ kinematic viscosity, viscosity index, conductivity and other detection indicators, truly realize the multi-functional small volume large integrated integrated application multi-functional online monitoring oil sensor.

Application field:Steel, petrochemical, shield, power, wind power, large equipment, OEM integration

Applicable oil:Gear oil, hydraulic oil, turbine oil, diesel oil, insulation oil

Up to 27 indicators will be monitored

ADAPTS to different field interfaces

Accurate and reliable data

Interface customizable

- Ports of different specifications can be customized based on requirements to adapt to onsite integrated installation

- Optional indicators, wide range of adaptation

- Highly integrated and maintenance-free

- Standardized data output facilitates data integration

Dimensions and installation

Working Condition

| Maximum oil temperature | Oil line pressure | Flow rate of oil circuit | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | ≤1m/s | -20℃-85℃ | 5000m | 2G | 95% |

Specificationr

| argument | range | precision | Resolution | CODE |

|---|---|---|---|---|

| Ferromagnetic particle | 30-800um | ≥95% | ferromagnetic≧30um | M3 |

| Non-ferromagnetic particles | 120-1600um | ≥95% | non-ferromagnetic≧120um | |

| Wear concentration | Real-time value | 1mg/l | 1mg/l | |

| 24H total number of particles | Real-time value | 1 | 1 | |

| Flow detection | Real-time value | 1ml/min | 1ml/min | |

| Moisture content | 0-10000ppm | ±10% | 1ppm | W2A |

| Saturation | 0-1aw | ±0.04 | 0.01aw | W2A |

| Moisture content | 0-100% | ±0.03%(Maximum range) | 0.01% | W2B |

| Oil quality | 1-80 | ±3% | 0.01 | V4 |

| Dynamic viscosity | 10-1200CP | ±3% | 0.01cp | |

| temperature | 20℃-85℃ | 0.1℃or ±3% | 0.01℃ | |

| density | 600 ~1500 kg. m³ | ±3% | 0.01kg. m³ | |

| Supporting flange: SAE\DN\ boat mark (optional) | ||||

| Options: real-time kinematic viscosity, V40 viscosity, V100 viscosity, viscosity index, conductivity | ||||

According to the field needs, can be matched with the model group number, such as monitoring gear oil, can be combined with the codeISL-Z/M3/W2B/V3

The accuracy corresponding to the above performance parameters is the typical value of 25℃. In the case of exceeding the requirements of the system working condition, the data may be biased, and the accuracy will change according to the pressure, flow rate, vibration and other data.

Electrical properties

| Communication interface | Data transmission | power | voltage | weight | Shell material | Cable length | Class of protection |

|---|---|---|---|---|---|---|---|

| 6 core jet jack | RS485/232 | ≤5W | DC 9V~36V | 4500G | 316L | 1.5m | IP65 |

The above performance indicators are suitable for conventional industrial site installation and use, encounter complex and harsh outdoor environment and fluid property changes, customized design according to site requirements, you can also contact our sales engineers for recommendations