Custom series

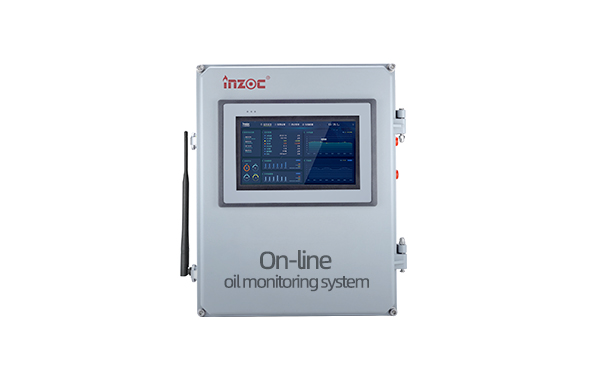

Distributed on-line oil monitoring system

The distributed on-line oil monitoring system adopts the form of multi-channel signal acquisition, aiming at the characteristics of high dispersion and multi-point in large industrial sites The system adopts multi-channel and single point acquisition information, summarizes the data in the sub-control system, and carries out centralized packaging and processing data, and realizes the realization The single point acquisition - centralized upload of the field greatly saves the deployment cost of traditional enterprises, and the main control system integrates 4G communication module and display screen The sensor connected to the data processing module and sub-control system can be independently matched and replaced according to the on-site monitoring requirements, which is suitable for industry Mass deployment on site, to achieve systematic multi-point joint monitoring, to help equipment early fault operation and maintenance to achieve a large number of data acquisition Take. Suitable for the integrated installation of steel mills, paper, petrochemical, cement, power system and other equipment, can adapt to viscosity, density, dielectric constant Measurement of number, moisture content, temperature, wear particles, and optional with internal model data: real-time kinematic viscosity, 40℃ movement Viscosity, 100℃ kinematic viscosity, viscosity index, conductivity and other detection indicators, truly achieve multi-function, low-cost, large integration The integrated application of multi-functional on-line monitoring oil system.

Application field:Steel, petrochemical, shield, power, wind power, large equipment, OEM integration

Applicable oil:Gear oil, hydraulic oil, turbine oil, diesel oil, insulation oil

IFV series multi-parameter oil sensor adopts patented multi-function integrated detection technology, with FOS model data, with industry-leading The back-end data processing module constitutes a large range, high precision, multi-functional oil comprehens- ive detection sensor, greatly reducing the on-line It is a representative product with large range and multiple parameters in the oi- l monitoring industry.The sensor viscosity, density index adopts the industry advanced precision resonant mechanism, dynamic vis- cosity detection can reach 1200CP; Internal integration The dynamic viscosity, density, dielectric constant, Moisture content, tem- perature detection, with internal model data can be selected: real-time kinematic viscosity, 40℃ kinematic viscosity, 100℃ Kinem atic viscosity, viscosity index, electrical conductivity and other testing indicators, truly achieve multi-functional small volume integ- ration of the comprehensive application of more Function online monitoring oil sensor.

system structure

Working Condition

| Maximum oil temperature | Oil line pressure | Flow rate of oil circuit | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | ≤1m/s | -20℃-85℃ | 5000m | 2G | 95% |

Specificationr

| argument | range | precision | Resolution | CODE |

|---|---|---|---|---|

| Moisture content | 0-10000ppm | ±10% | 1ppm | W2A |

| Saturation | 0-1aw | ±0.04 | 0.01aw | W2A |

| Moisture content | 0-100% | ±0.03(Maximum range) | 0.01% | W2B |

| Oil quality | 0-100 | ±3% | 0.01 | F2 |

| Dynamic viscosity | 10-1200CP | ±3% | 0.01cp | V4 |

| temperature | 20℃-85℃ | 0.1℃or±3% | 0.01℃ | |

| density | 600 ~1500 kg. m³ | ±3% | 0.01kg. m³ | |

| Control system: Select the control system based on the actual configuration | ||||

| Options: real-time kinematic viscosity, V40 viscosity, V100 viscosity, viscosity index, conductivity | ||||

According to the field needs, can be matched with the model group number, such as monitoring gear oil, can be combined with the code

The accuracy corresponding to the above performance parameters is the typical value of 25℃. In the case of exceeding the requirements of the system working condition, the data may be biased, and the accuracy will change according to the pressure, flow rate, vibration and other data.

Electrical properties

| Communication interface | Data transmission | power | voltage | weight | Shell material | Cable length | Class of protection |

|---|---|---|---|---|---|---|---|

| 6 core jet jack | RS485/232 | ≤5W | DC 9V~36V | 1000G | Aluminum product | custom | IP65 |

The above performance indicators are suitable for conventional industrial site installation and use, encounter complex and harsh outdoor environment and fluid property changes, customized design according to site requirements, you can also contact our sales engineers for recommendations