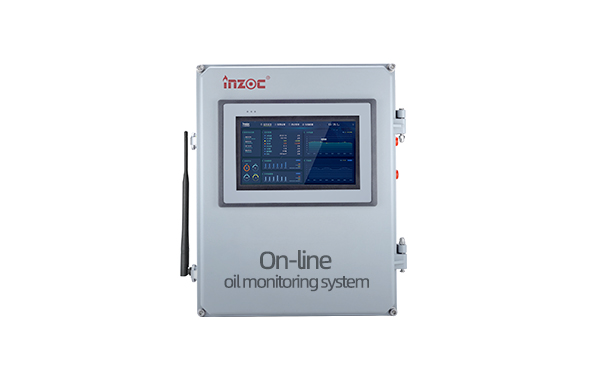

online

Abrasive image recognition and monitoring system

The online wear particle recognition system combines image recognition and abrasive particle analysis software to carry out 24h visual analysis of equipment wear status. It can reflect the wear particles, wear type, particle diameter and particle concentration of the equipment in real time, and the high-precision sensor can be recognized at the minimum The wear of 1um is distinguished, and the contour size of the specific topography is given, and the bubbles, water droplets, impurities, fibers and so on can be effectively distinguished External influence substances, the product is suitable for gear oil, hydraulic oil, diesel oil, system built-in expansion module, according to the field monitoring needs The particle counter and moisture sensor are selected to detect the comprehensive aging index of oil products. The system also has a wireless transmission module, To achieve rapid docking with the cloud platform, through the mobile phone, PC to achieve real-time observation of data.

Application field:Steel, petrochemical, shield, power, wind power, large equipment, laboratory

Applicable oil:Hydraulic oil, turbine oil, diesel oil, gear oil, transformer oil

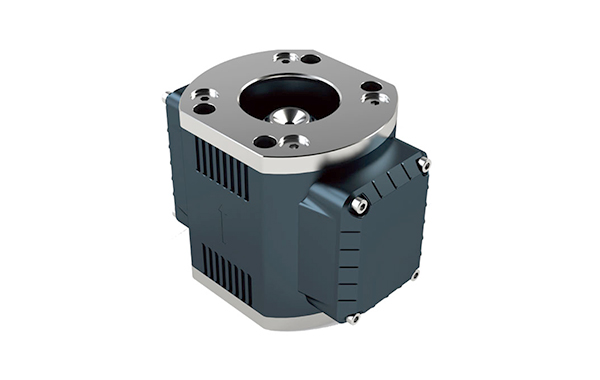

Ifm-vm series is used to analyze and detect the wear state of important mechanical parts. The products can identify abrasive pa- rticles through images Combined with analysis software, visual analysis of equipment wear state can reflect the wear particles, - wear types and particles of equipment in real time Particle diameter, particle concentration, etc., the high-precision sensor can recognize the wear of at least 1um, and give the profile of the specific morphology And can effectively distinguish qipao, water droplets, impurities, fibers and other foreign influence substances, products and gear oil, hydraulic oil, diesel oil, can also detect black engine, the product can also choose particle counter, moisture creation safety, to achieve comprehensive oil products Detection of aging indicators.

Functional features

Digital metal wear analysis technology/Digital wear analysis

Accurate analysis of ferromagnetic and non-ferromagnetic wear particles in oil products, can identify superimposed states, different forms, and can identify and analyze old factors such as bubbles, moisture, impurities. The particle distribution of ferromagnetic wear and non-ferromagnetic wear can be divided according to different grades

Wear grading can show different particle segments with up to 12 channel indicesThe minimum recognition accuracy is 1um, and can provide wear concentration, 24H wear total

Applicable condition/Working Condition

| Maximum oil temperature | Sample viscosity | Injection pressure | Operating ambient temperature | Highest altitude | Power source | Maximum humidity |

|---|---|---|---|---|---|---|

| -10~+60℃ | 1-600Cp | ≤3bar | -20℃-85℃ | 5000m | AC220 | 95% |

Detection range/Specificationr

| Wear detection | Particle count | hydration | Applicable oil | Working mode |

|---|---|---|---|---|

| Wear analysis, wear particle number | Particle distribution | Saturation | Mineral oil, hydraulic oil | Online/Offline |

| Total wear, particle size | Pollution level | Moisture content | Gear oil, steam turbine oil |

Performance parameter/Electrical properties

| Wear identification range | Abrasive particle concentration range | Image resolution | Particle counting range | hydration | Saturation |

|---|---|---|---|---|---|

| 1-800um | 0-2000ppm | 1920X1080 | 1um-600um | 0-10000ppm | 0-1Aw |

For detailed parameters, please contact us.