Large machinery including shield machines, die casting machines, fracturing trucks, large excavators, shearer need to install oil online monitoring to ensure normal operation. The main bearings of shield machine are mainly low-speed and heavy-duty bearings in the main transmission system. As an important bearing component of shield machine, the good condition of main bearing is related to the reliability of the whole shield machine to a large extent. The operating condition of shield machine main bearing is complicated. Once a failure occurs, if it cannot be maintained in time, it will lead to a rapid expansion of local failures, resulting in huge economic losses.

Program advantage

Breakpoint continuation

For the mobility of large moving machinery, the communication instability monitoring system has built-in breakpoint continuation function, which can temporarily store the data inside the system to ensure that the data is not lost.

High fit

Standardized installation interface design, the pressure interface of different equipment and different vehicles can be quickly adapted, and the unique structure can also adapt to different oil temperature environments.

Multilayer protection

Sensor 316L steel shell, the monitoring box is made of aviation aluminum, which can be easily handled in outdoor environment, and the equipment is equipped with leak monitoring to ensure safe operation.

The system has three deployment modes

Bypass monitoring

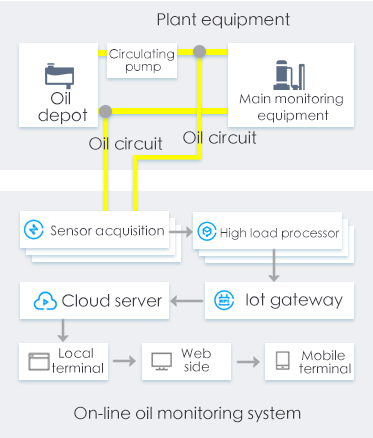

-On-line monitoring system

The online oil monitoring system adopts the form of main road opening or interface switching, such as the need to monitor the rolling mill oil road, select a suitable position in the main return pipeline of the rolling mill oil road, introduce the oil to the interface of online oil monitoring, and realize the oil circuit circulation. Data collection, data analysis, data display (localization), and data upload cloud servers can be integrated, truly saving worry, money and effort, and monitoring data is stable and reliable.

Main road monitoring

-Multi-point acquisition sensor

In different equipment, there are many key data points, and the method of multi-point collection and single point processing can greatly save costs. During installation, holes can be directly made in the system pipeline, and the sensor can be embedded in the pipeline. The sensor is designed to resist corrosion, impact, pressure and high stability, and can collect multi-point oil aging information during system operation. Discover unexpected faults such as water intake and pollution in time, quickly locate the fault location, and achieve accurate collection.

Main road monitoring

-Multifunctional sensor

The main road multi-function monitoring is suitable for the transformation of the lubrication system and the use of large-area deployment. The sensor is installed by using flange transfer or pipeline transformation on the lubrication pipe road. The sensor is suitable for the installation of a variety of different standard flanges and different pipe diameters, and the internal integration of a variety of monitoring indicators. The data can be uploaded and displayed in a centralized mode to maximize the economic effect.

Application of large mechanical equipment

Customer case

They all trust our oil monitoring technology

Four engine Seva

Build reliable oil analysis system together with oil extraction equipment manufacturers

Provide customers with pre-installed product design, applied to mobile cementing vehicles, fracturing trucks and other heavy special vehicle sensor system built-in wear sensor, moisture sensor, viscosity sensor, according to the customer's vehicle equipment special oil, pre-implanted model curve, to provide reliable support for equipment data analysis.

Xugong Group

Provides reliable integrated oil monitoring technology

To provide customers with support on the underlying technology of the sensor, jointly create a reliable oil analysis instrument, the two sides conducted in-depth research and discussion on the monitoring of diesel oil, and improved a large number of viscosity algorithms for construction machinery in the high temperature working environment to achieve a high degree of reliability of data acquisition.

China First Heavy Group

Qiqihar China One heavy Group - operator hydraulic station

Predictive maintenance of large equipment is crucial, once the situation of unplanned shutdown, will increase the possibility of major safety accidents, intelligent match oil online monitoring system is a good solution to this state of the enterprise.

China Railway Group

Guangzhou China Railway shield machine hydraulic system main pump

In the complex underground tunnel drilling conditions, real-time oil online monitoring is particularly important, the diesel oil independently developed online monitoring system is a good solution to this problem, to provide a solid guarantee for the safe operation of equipment.